Durable metal plank for multi-purpose construction projects

What is Metal Plank

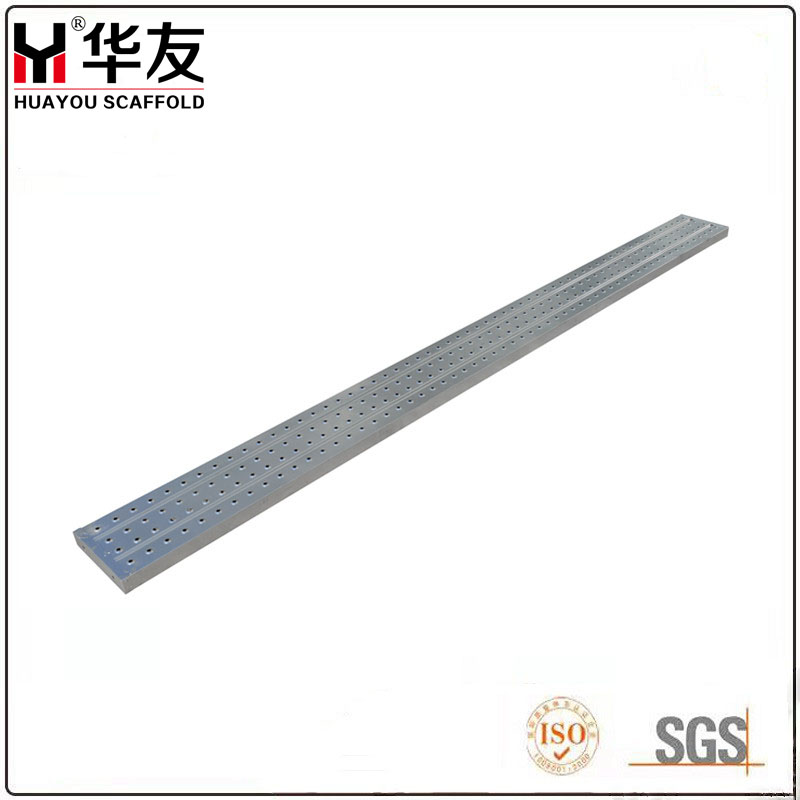

Metal panels, often called steel scaffolding panels, are strong and durable components used in scaffolding systems. Unlike traditional wood or bamboo panels, steel panels have greater strength and longevity, making them the first choice for construction projects. They are designed to support heavy loads, ensuring workers can operate safely at different heights.

The transition from traditional materials to sheet metal represents a significant advance in architectural practice. Not only are steel planks more durable, they are also resistant to weather conditions, reducing the risk of wear and tear over time. This durability means lower maintenance costs and greater efficiency on the job site.

Product description

Scaffolding Steel planks have many name for different markets, for example steel board, metal plank, metal board, metal deck, walk board, walk platform etc. Until now, we almost can produce all different types and size base on customers requirements.

For Australian markets: 230x63mm, thickness from 1.4mm to 2.0mm.

For Southeast Asia markets, 210x45mm, 240x45mm, 300x50mm, 300x65mm.

For Indonesia markets, 250x40mm.

For Hongkong markets, 250x50mm.

For European markets, 320x76mm.

For Middle east markets, 225x38mm.

Can be said, if you have different drawings and details, we can produce what you want according to your requirements. And professional machine, mature skill worker, large scale warehouse and factory, can give you more choice. High quality, reasonable price, best delivery. Nobody can refuse.

The composition of steel plank

Steel plank consists of main plank, end cap and stiffener. The main plank punched with regular holes , then welded by two end cap at two sides and one stiffener by every 500mm. We can classified them by different sizes and also can by different type of stiffener, such as flat rib, box/square rib, v-rib.

Size as following

|

Southeast Asia Markets |

|||||

|

Item |

Width (mm) |

Height (mm) |

Thickness (mm) |

Length (m) |

Stiffener |

|

Metal Plank |

210 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

240 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

|

250 |

50/40 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

300 |

50/65 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

The Middle east Market |

|||||

|

Steel Board |

225 |

38 |

1.5-2.0mm |

0.5-4.0m |

box |

|

Australian Market For kwikstage |

|||||

| Steel Plank | 230 | 63.5 | 1.5-2.0mm | 0.7-2.4m | Flat |

| European Markets for Layher scaffolding | |||||

| Plank | 320 | 76 | 1.5-2.0mm | 0.5-4m | Flat |

Product Advantage

1. Steel panels, often referred to as scaffolding panels, are designed to replace traditional wooden and bamboo panels. Its sturdy structure offers several advantages, making it ideal for multi-purpose construction projects.

2. The durability of steel ensures that these planks can withstand heavy loads and harsh environmental conditions, reducing the risk of breakage or failure. This reliability is critical to the safety of construction sites where maintenance risks are high.

3. Steel panels are resistant to rot, insect damage, and weathering, which are common problems with wood panels. This longevity means lower maintenance costs and less frequent replacement, making them a cost-effective option in the long run.

4. Additionally, their uniform size and strength allow for easier installation and better compatibility with various scaffolding systems.

Product Effect

The benefits of using durable metal plank go beyond safety and cost-effectiveness. They help streamline workflows because workers can rely on consistent performance without the unpredictability that comes with traditional materials. This reliability creates a more efficient work environment, ultimately leading to timely project completion.

Why choose Metal Plank

1. Durability: Steel panels are able to withstand weather conditions, rot, and pests, ensuring they last longer than wooden boards.

2. Safety: Steel plates have a higher load-bearing capacity, which reduces the risk of accidents on site, making it a safer choice for construction projects.

3. VERSATILITY: These planks can be used in a variety of applications, from scaffolding to formwork, making them a versatile solution for any construction need.

FAQ

Q1: How does steel plate compare to wood panel?

A: Steel panels are more durable, safer and require less maintenance than wood panels.

Q2: Can steel plates be used for outdoor projects?

Answer: Of course! Their resistance to weather conditions makes them ideal for indoor and outdoor use.

Q3: Is the steel plate easy to install?

A: Yes, the steel plates are designed to be easy to install and can be installed and removed quickly.